| 1/6 | 009 Return to MSR&LHA Home page |

|

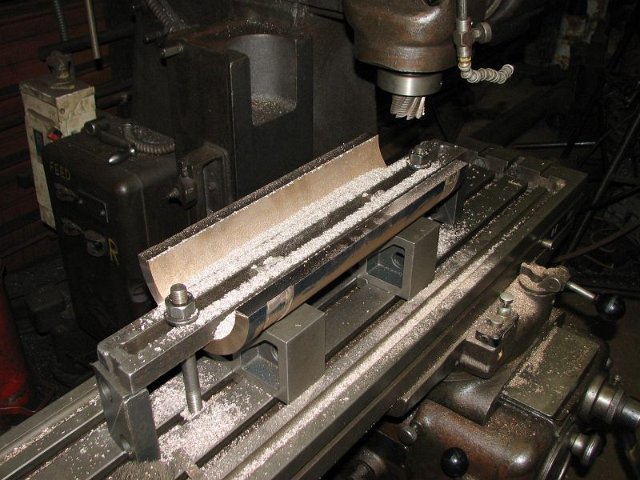

Milling the sleeve to a "half-pipe". The outside diameter of this casting has already been machined, and the locating nipples filed to match the holes in the crossbox. With these two tasks done, the bronze was clamped into the crossbox and lines were scribed to define the required height of the finished half-pipe. After leveling up according to the layout lines, the casting was strapped down to the V-blocks, and milled down to these layout lines. Three cuts on each side is the usual order of business: two bigger cuts, and one light finishing pass. Could most likely be done in two, but why take the chance in ruining many hours of work, and a good casting?

Photo by Rick Brigger. |