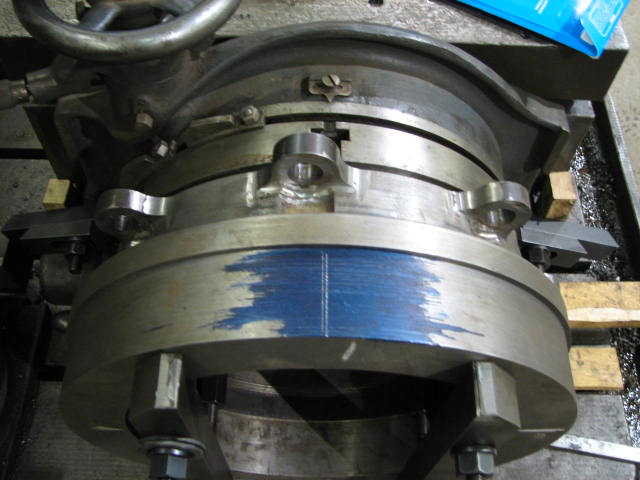

A 16 inch diameter rotary table was borrowed, which made the spacing and drilling of the 20 rivet holes around the perimeter of the ring an easy job. During BOD weekend, the stack ring was bolted to the table and indicated for truth. This was done with the rotab positioned flat on top of the radial drill's table, to make life much easier. This Saturday morning the rotab and work piece were clamped to the side of the table, with the help of a fork-lift, in order to position the axis of the ring 90 degrees to the drill spindle. The blue portion of the ring is a bit larger than 18 inch, so to find the approximate center line, we measured in 9 inches from each side, with the resulting gap between the two lines. We figured if we could place the holes between the lines, that it would be plenty good enough for rivet holes.

How does a rotary table work? Through a worm drive, a rotary table may be rotated a full 360 degrees. The table rotation is controlled by the spoked wheel at the top left of the photo: one wheel rotation moves this table 3 degrees. Twenty evenly-spaced holes about a circle works out to 18 degrees between holes. Between holes, the hand wheel must be turned six rotations for proper spacing. The adjustable pointer on the gray table base points to degree markings.

Photo by Rick Brigger

|

| File size | 59147 |

| Original date | 1/14/12 11:59 AM |

| Resolution | 640 x 480 |

| Flash | Flash did not fire, auto |

| Focal length | 6.0mm |

| Exposure time | 1/8s |

| Aperture | 2.7 |

| Focus Distance | |

| Metering Mode | Multi-segment |

| Camera make | Canon |

| Camera model | Canon PowerShot S2 IS |

| Sensor type | OneChipColorArea |

|